Product Description

JR-12 (Coverd Electrodes for Mild Steel)

Characteristics

JR-12 is a high-oxidant titanium welding rod with excellent workability and has a beautiful bead appearance.

In particular, the arc is quiet and smooth, creating minimal spatter and has fine slag removal.

It is suitable for welding light or thin-walled structure as the penetration is relatively shallow.

Purpose

General machinery, automobiles, Thin-walled structure, Thick-plate structure, Beauty Welding, Pipe, Water Tank

Operation precautions

Dry the cladding at 70~100℃ for 30~60 minutes if the arc turn unstable when it absorbed excessive cladding, performing unstable melting state, increased spatter, and undercutting or fitting.

Use within the proper current rage as welding at a current too high will reduce the X-ray performance, increase spatter, and cause undercuts.

Mechanical Properties of Welded Metal

| Yield Point N/㎟(kg/㎟) | Tensile Strength N/㎟(kg/㎟) | Elongation(%) |

|---|---|---|

| 430(44) | 480(49) | 29 |

Chemical Properties of Welded Metal(%)

| C | Si | Mn | P | S |

|---|---|---|---|---|

| 0.07 | 0.32 | 0.38 | 0.018 | 0.014 |

Suitable Current per Welding Current(DC+)

| Rod diameter(mm) | 2.6 | 3.2 | 4.0 | |

|---|---|---|---|---|

| Rod length(mm) | 350 | 350 | 400 | |

| Current(A) | Vertical Down, Horizontal Fillet | 45~95 | 80~130 | 110~180 |

| Vertical Up | 45~90 | 80~110 | 100~160 | |

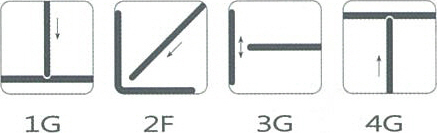

Welding Method