Product Description

JSF-71T (Mild and 490MPa tensile strength steel)

Characteristics

JSF-71Tis a titanium fluxed cored wire, designed for all types of welding methods.

Arc is relatively stable than Co₂ solid wire, the spatter particles are small and little

- The bead has a beautiful exterior, so it has a great spread.

The Slag can be fully covered, detachability is excellent, and the crack-resistance is particularly outstanding.

Purpose

Butt and fillet welding, including Shipbuilding, Automobile, Bridge, Construction, Steel Structure, and more.

Operation precautions

Although it varies depending on the rigidity, thickness, and binding, a general suitable preheating (50 to 150 °C) is required to prevent low-temperature cracks.

Be cautious as high current and high-speed welding can cause high-temperature cracks in the root pass bead during flat-panel welding.

100% Co₂ is used as protection gas.

Mechanical Properties of Welded Metal

| Yield Point N/㎟(kg/㎟) | Tensile Strength N/㎟(kg/㎟) | Elongation(%) | Shock Value J(kgf·m(0℃) | Hydrogen Level (㎤/100g) |

|---|---|---|---|---|

| 520(53) | 582(59) | 28 | 110(11) | 8.0 |

Chemical Properties of Welded Metal(%)

| C | Si | Mn | P | S |

|---|---|---|---|---|

| 0.04 | 0.49 | 1.29 | 0.01 | 0.009 |

Suitable Current per Welding Current(DC+)

| Rod diameter(mm) | 1.2 | 1.4 | 1.6 | |

|---|---|---|---|---|

| Rod length(mm) | F&HF | 120~300 | 200~350 | 200~400 |

| V-up&OH | 120~260 | 180~280 | 180~280 | |

| V-down | 200~300 | 220~320 | 250~300 | |

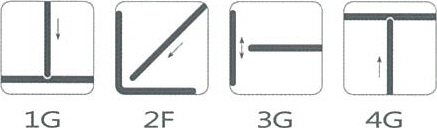

Welding Method

Approval

| Approval | ABS | DNV-GL | LR | KR | NK |

|---|---|---|---|---|---|

| Grade | 2YSAH15 | Ⅱ-YMS(H10) | 2YSH15 | 2YSG(C)H15 | KSW52G(C)H10 |